- Description

-

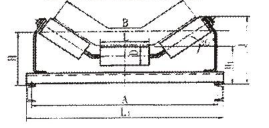

The cone-type centering roller is the use of cone-type roller of different linear speed of the adjustment mechanism, which to prevent and correct the conveyor belt deviation.

The friction self-aligning roller has a strong ability to prevent the damage and deviation of the conveyor belt, and the deviation mechanism of friction resistance and friction wheel arc is used to prevent and correct the deviation of the conveyor belt.Data idler

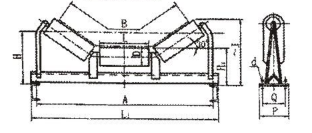

Trough idler Rubber ring type buffer roller Pring plate buffer idler

Description:

1. Fasteners connected to the rack are included in this assembly drawing.

2. There are three types of idler rollers: seamless steel pipe with stamped bearing seat, cast iron bearing seat and fully reinforced plastic. (Buffer idler without full reinforced plastic roller). Roller

There are two kinds of axes: light pull axis and step axis.

3. Weight in the table: outside the brackets is the stamped bearing seat with seamless steel pipe for the light-drawn shaft, and inside the brackets is the cast iron bearing seat with seamless steel pipe for the stepped shaft. The weight of the all-plastic idler is △kg lighter than that of the seamless steel pipe stamping seat idler.B 500 650 800 1000 1200 1400 △ 5 6 7.5 12 14 17 4.When there are no special requirements for different combinations of pipes and bearing seats, the manufacturer shall decide at its own discretion.

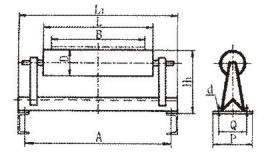

B A L L1 H H1 D P Q d J Rolling

bearing type

Trough idler

Spring plate

buffer idler

Rubber ring type

buffer roller

Weight Figure No. Weight Figure No. Weight Figure No. 500 720 190 760 210 170 89 170 130 M12 270 204 17 (21) TD1C1 23 (27) TD1C7 21 TD1C9 650 870 240 910 230 295 20 (23) TD2C1 29 (31) TD2C7 25 TD2C9 800 1070 305 1110 240 330 24 (27) TD3C1 33 (37) TD3C7 30 TD3C9 1000 1300 375 1350 300 210 108 220 170 M16 400 305 41 (50) TD4C1 53 (62) TD4C7 32 TD4C9 1200 1550 455 1610 330 230 260 200 460 55 (64) TD5C1 62 (71) TD5C7 38 TD5C9 1400 1750 525 1810 350 495 61 (71) TD6C1 78 (87) TD6C7 77 TD6C9 Parallel upper idler Parallel lower idler

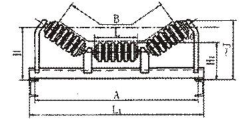

Note:

1. Fasteners connected to the middle frame are included in the assembly drawing.

2. There are two types of idler rollers: seamless steel pipe with stamping bearing seat and cast iron bearing seat. Roller shaft has two kinds of light pull shaft and stepped shaft.

3. In the bracket of the weight 1 column, the stepped shaft is equipped with seamless steel pipe cast iron seat, and outside the bracket, the light drawing shaft is equipped with seamless steel pipe stamping seat.

4. In the table, the value of the flat lower idler is below the oblique line, and the value of the flat upper idler is above.

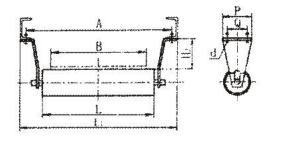

5. When there are no special requirements for different combinations of pipes and bearing seats, the manufacturer shall decide on its own.B A L L1 H1 H2 D P Q d Rolling

bearing type

Parallel upper idler

Parallel lower idler Weight Figure No. Weight Figure No. 500 720 600 760 210 55.5 89 170/100 130/60 M12 204 15(16) TD1C1 10(12) TD1C3 650 870 750 910 230 17 (19) TD2C1 12(14) TD2C3 800 1070 950 1110 240 21 (23) TD3C1 14(19) TD3C3 1000 1300 1150 1350 300 46 108 220/130 170/80 M16 305 37 (41) TD4C1 23(27) TD4C3 1200 1550 1400 1610/1600 330 260/130 200/80 48(54) TD5C1 27(32) TD5C3 1400 1750 1600 1810/1800 350 55(61) TD6C1 31(36) TD6C3 Specification:Φ60,Φ76,Φ89,Φ108,Φ114,Φ127,Φ133,Φ159,Φ194 and other nine series.

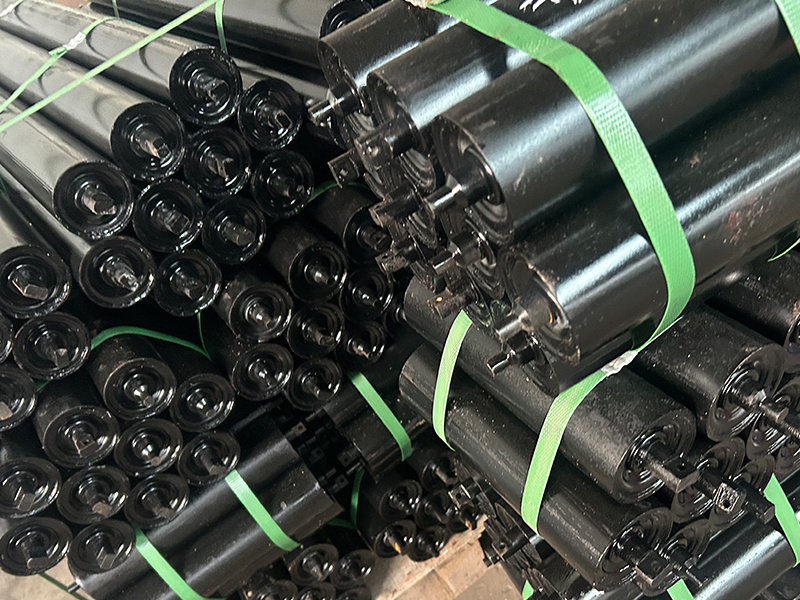

Features:Tested by the National Quality Supervision and Inspection Center for Lifting and Transportation Machinery, it fully meets the standard requirements of GB/T10595-1989 by adopting high-quality welded steel pipe, stamped bearing seat, and special clearance bearing for KA rollers. At the same time, the new combination of contact and non-contact seals newly developed by our factory is used, which has better dustproof and waterproof performance, and the bearing housing has good coaxiality and low rotational resistance. The whole processing process from unloading to finished products adopts non-floor type processing technology flow with high automation degree.

TD75 Fixed Belt Conveyor Roller Catalog

Serial number Name Specification Figure number Bandwidth 1 Grooved Roller Φ89*190 TD1C1 500 Φ89*240 TD2C1 650 Φ89*305 TD3C1 800 Φ108*375 TD4C1 1000 Φ108*455 TD5C1 1200 2 Parallel Upper Roller

Parallel lower rollersΦ89*600 TD1C2 500 Φ89*750 TD2C2 650 Φ89*950 TD3C2 800 Φ108*1150 TD4C2 1000 Φ133*1400 TD5C2 1200 Φ133*1600 TD6C2 1400 3 Groove type centering rollers Φ89*190 TD1C 4 500 Φ89*240 TD2C 4 650 Φ89*305 TD3C 4 800 Φ108*375 TD4C 4 1000 Φ108*455 TD5C 4 1200 Φ108*525 TD6C 4 1400 4 Parallel top centering rollers

Parallel downward aligning rollersΦ89*600 TD1C 5 TD1C 6 500 Φ89*750 TD2C 5 TD2C 6 650 Φ89*950 TD3C 5 TD3C 6 800 Φ108*1150 TD4C 5 TD4C 6 1000 Φ133*1400 TD5C 5 TD5C 6 1200 Φ133*1600 TD6C 5 TD6C 6 1400 DSJ-80 Telescopic Belt Conveyor Roller Catalog

Serial number Name Specification Figure number Bandwidth 1 Articulated rollers Φ89*275 SBD Change 800 2 Flat Roller Φ89*950 SBD Change 800 3 Buffer rollers Φ89*275 2Sa170402A 800 DSJ-100 Telescopic Belt Conveyor Roller Catalog

Serial number Name Specification Figure number Bandwidth 1 Articulated rollers Φ108*360 DSP 503B 1000 2 Flat Roller Φ108*1150 DSP 501B 1000 3 Buffer rollers Φ108*360 DSP 624 1000 DSJ-120 Telescopic Belt Conveyor Roller Catalog

Serial number Name Specification Figure number Bandwidth 1 Upper articulating rollers Φ133*465 UT11G -00 1200 2 Lower articulated rollers Φ133*700 UT12G-00 1200 3 Flat rollers Φ133*1400 UT19G-00 1200 4 Cushion roller Φ133*465 UT21G-00 1200 DSJ-140 Telescopic Belt Conveyor Roller Catalog

Serial number Name Specification Figure number Bandwidth 1 Grooved rollers Φ159*530 AOT-02-00 1400 2 V-shaped lower rollers Φ159*760 P14.0509-00 1400 3 Parallel Lower Roller Φ159*1500 P14.0306-00 1400 4 Buffer rollers Φ133*465 P1 4.060702 1400 DTI Fixed Belt Conveyor Roller Catalog

Serial number Name Specification Figure number Bandwidth 1 Transition rollers

Grooved (forward tilting) rollersΦ89*250 DT II GP1102 650 Φ89*315 DT II GP1103 800 Φ108*380 DT II GP1104 1000 Φ133*465 DT II GP1105 1200 2 Buffer rollers Φ89*200 DT II GH1101 500 Φ89*250 DT II GH1102 650 Φ89*315 DT II GH1103 800 Φ108*380 DT II GH1104 1000 Φ133*465 DT II GH1105 1200 Φ159*530 DT II GH1105 1400 3 Friction upper aligning rollers Φ89*200 DT II 01C11 11 500 Φ89*250 DT II 01C11 12 650 Φ89*315 DT II 01C11 13 800 Φ108*380 DT II 01C11 14 1000 4 Parallel lower rollers Φ89*600 DT II GP11 07 500 Φ89*750 DT II GP11 09 650 Φ89*950 DT II GP11 11 800 Φ108*1150 DT II GP1112 1000 Φ133*1400 DT II GP11 13 1200

Company Profile

Baoding Wanjia Conveying Machinery Manufacturing Co., Ltd. is a professional enterprise producing various kinds of conveyor belts, conveying machinery and accessories. Since its establishment, the company has always adhered to the business philosophy of developing enterprises based on science and technology, emphasizing quality management, pursuing good faith management and creating famous brand products. High-quality scientific and technological management team, advanced production equipment, complete testing methods, strict quality control system to ensure the production of high-quality, efficient products. The company is based on the domestic market, closely with the international norms. The company has been awarded “Certificate of Adoption of International Standards” issued by Hebei Provincial Bureau of Technical Supervision and “Certificate of Product Conformity” issued by Hebei Provincial Product Quality Supervision and Inspection Institute, and passed ISO9001 International Quality System Certification in 2005. The ordinary, high-temperature resistant and whole-core flame retardant conveyor belts produced by the company have been sold well all over the country and exported to Southeast Asian countries with their good product quality and considerate after-sales service. The products are widely used in coal, metallurgy, harbor, electric power, building materials and other production fields.

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery

Delivery site

Previous:

Next:

Aligning roller

If you need customized delivery products, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products