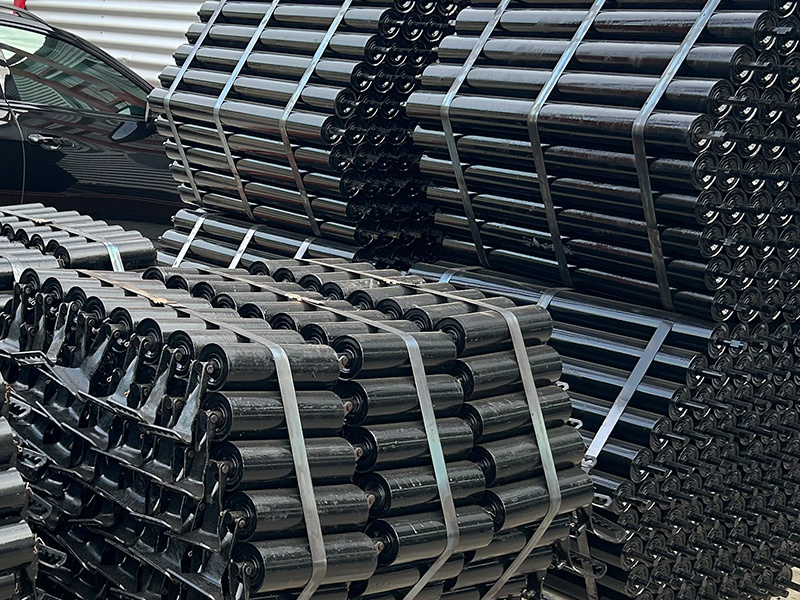

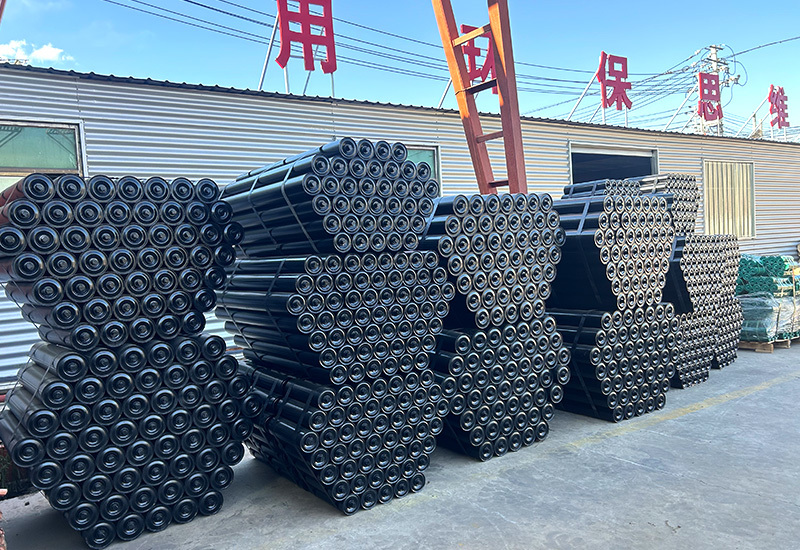

Roller is an important part of belt conveyor

The idler is installed on the belt conveyor to support the belt, so that the overhang of the belt does not exceed the technical requirements, and to ensure the smooth operation of the belt. At the same time, the idler can support the conveyor belt and the weight of the material, and is a vulnerable part of the belt conveyor.

The roller is mainly composed of roller body, bearing, sealing ring, shaft and so on:

Roller body: usually rubber, metal, polymer materials or ceramics and other materials, with wear-resistant, anti-corrosion characteristics.

Bearing: responsible for reducing the resistance and wear during the rotation of the drum.

Seal ring: to prevent dust and moisture into the bearing, to ensure the good running state of the roller.

Shaft: The key part connecting the roller body with the bearing.

In addition, the roller by the tube, the center shaft, bearing seals are also more common.

When the material on the conveyor belt is subjected to gravity or traction, the friction between the roller and the conveyor belt is used to smoothly transport the material to the destination along the belt direction.

TAG:

Related Posts

Why do PVC conveyor belts need to be wrapped?