Applicable industry and composition of skirt conveyor belt?

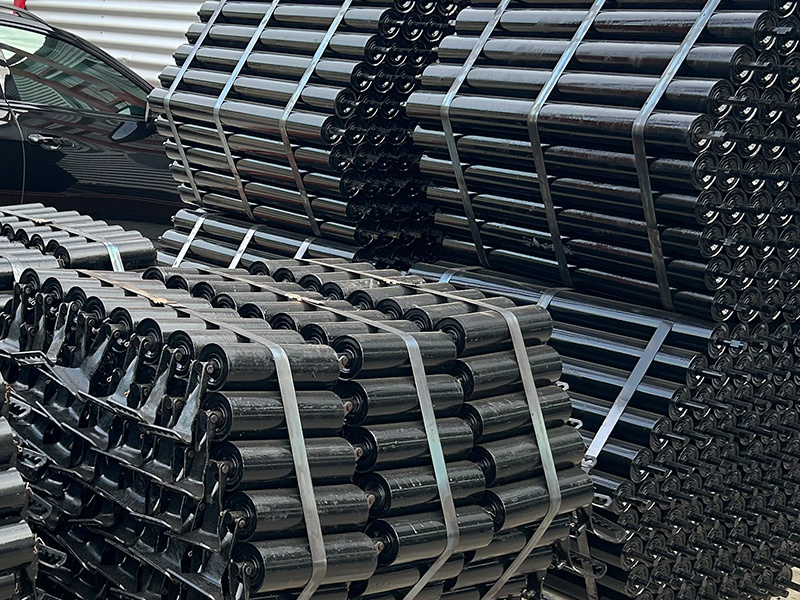

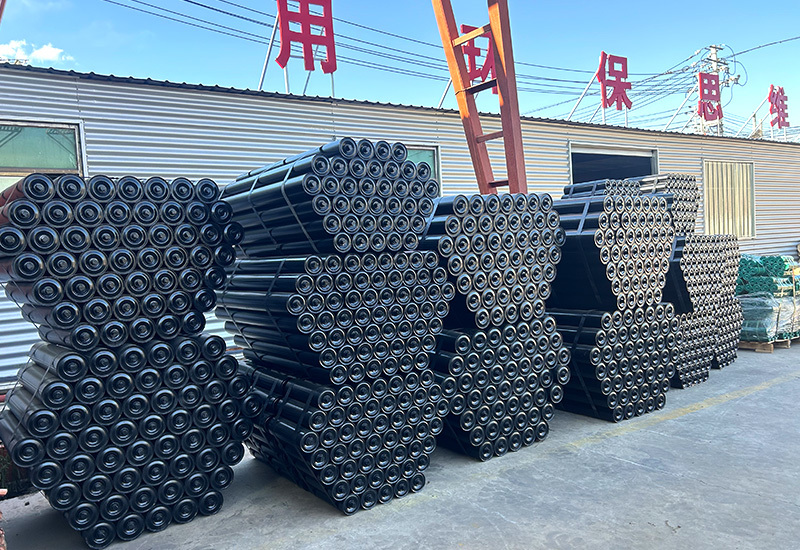

Skirt conveyor belt is a kind of transmission equipment with rubber, polyurethane, nylon, polyester and other main materials and multi-layer fabric or steel wire reinforced materials. The conveyor belt is mainly suitable for the following industries.

First of all, the skirt conveyor belt is widely used in the food processing industry. Such as bread processing, candy processing, potato chips production and other industries. These industries require transportation equipment, so skirt conveyor belts are used to achieve fast, safe and logistics transportation.

Secondly, it also has a wide range of applications in the chemical industry. Skirt conveyor belts can be used for conveying chemical products, such as polyester pellets, plastic pellets, etc. Because these products are flammable, explosive, corrosive and other characteristics, it is necessary to use professional conveying equipment, and skirt conveyor belt is the choice in this regard.

In the textile industry can also see the figure of the skirt conveyor belt. It can be applied to various yarn transportation, such as the transportation of the spindle to the spinning machine, the transportation of the drawing frame to the tractor, etc. These industries have higher requirements for the wear resistance and high temperature resistance of the conveyor belt, and the skirt conveyor belt can meet these requirements.

Skirt conveyor belt is composed of three parts: main frame, rubber belt and transverse reinforcement layer. The main frame provides support for the conveyor belt, the rubber surface belt plays a role in transmitting power and carrying materials, and the transverse reinforcement layer has the function of preventing the conveyor belt from stretching and deforming.

In summary, the skirt conveyor belt has a wide range of applications in food processing, chemical industry and textile industry. It is characterized by wear resistance, high temperature resistance, corrosion resistance, and has good bearing capacity and excellent force transmission effect. This equipment can not only improve production efficiency, but also ensure product quality, so it is worth promoting and using.

TAG:

Related Posts

Why do PVC conveyor belts need to be wrapped?